Filtration systems

Our Geminos range can use either Fleck or Autotrol valves.

We stock a comprehensive range of pre-engineered filtration and ion exchange systems, to handle a wide variety of feedwaters. Single unit capacities range from 0.5m3/hr – 50m3/hr with most filters based around our Pentair structural vessels and Fleck or Clack multiport valves. We can also offer multi vessel systems with the associated pipework and valving.

pH Correction units

When rain falls, the water has a naturally aggressive, slightly acidic nature. This water then dissolves chalk and/or metallic deposits present in the local rock strata which leads to the contamination of the water. This results in ground and borehole water containing a number of elements that would not otherwise be present in mains water. These contaminants (such as Iron and Manganese) then cause problems when the water is put into use.

Acidic water results in corrosion of pipework, heating cylinders and equipment. Any Iron and Manganese present will result in poor tasting water, in addition to staining baths, basins and any appliances with which the water may come into contact.

A pH value of below 7 is considered to be acidic, and corrosion accelerates at pH levels below 6.5, with levels below 6.0 considered to be extremely aggressive. It is usually difficult to remove Iron and Manganese from acidic water, so often the first step in the process is to raise the pH.

The simplest and safest way to raise the pH is to run the water through a pressure vessel containing a bed of specially activated limestone (Juraperle). This is a mixture of Calcium and Manganese salts, which are the salts found in waters of pH greater than 7. This limestone gradually dissolves, increasing the pH level of the water. As the limestone dissolves, it will need refilling periodically. Refilling is straightforward as the media is inert and easy to handle.

To treat waters that are otherwise clean and pure, a basic manual (up-flow) filter is all that is required. For water with Iron, Manganese or turbidity problems, an automatic back-washing down-flow system will be needed to remove accumulated debris.

The contact time of the water with the pH correction media is important in achieving consistent results. Please refer to the technical data sheet for more details on each of the filter sizes.

For every 10 mg/L CO 2 present in the water, the alkalinity and total hardness will be raised 18mg/L as CaCO 3. For each 10 mg/L CO 2 removed, there will be a consumption of approximately 12 mg/L of media. In reality it’s quite difficult to determine how much media will be used and it’s worth checking the level of the media bed regularly and replenishing as required.

Activated Carbon Filters

Activated Carbon is a specialized filter media used principally for removing Chlorine or organic compounds from water. Most of the activated Carbon used for water treatment is made from baking crushed coconut shells until it produces a charcoal type material. This is then activated with high pressure steam, leaving the carbon with many minute active pores on its surface. The ability of Activated Carbon to remove contaminants from raw water is dependent upon the length of time the water spends in contact with the media. Therefore sizing the filters correctly is crucial for effective performance.

Organic compounds are often responsible for taste, odour, and colour problems in surface waters. Contamination may occur from dead, decaying vegetable matter, agricultural runoff containing herbicides & pesticides or leakage of underground gasoline containers. With organic removal, the contaminant molecules are trapped and retained on the Carbons surface, and eventually all of the media will become “blinded” and will need to be changed. The frequency of changing will again depend upon the level of water contamination. The effectiveness of Carbon at removing organic compounds such as pesticides and solvents varies according to the precise nature of the contaminant.

Chlorine removal with Carbon is a “Catalytic” process in which the media does not become blinded or exhausted, but instead it acts as a trigger to the de-chlorination process. The active sites on the surface of the media do eventually become blinded by other contaminants in the raw water (such as Iron or organic material) which means that the media will need to be changed every 1 to 3 years depending on the water quality. Carbon filters are often used to remove Chlorine on the inlet to reverse osmosis systems, avoiding potential oxidation of the membrane flat sheet.

The Technical Data Sheet shows flow rate information for each size of filter. These figures are based on removal of organics which is a slower process than the removal of Chlorine. A range of different vessel sizes are available along with a range of valves from Fleck and Clack. Sizing is based on a contact time of 6 minutes (for colour and organics removal). For de-chlorination only, siziong can be based on a contact time of 2 minutes. If the Carbon filter is being used just to remove Chlorine then it’s possible to use a manual system with no backwash. This consists of a manual head with either 3/4” or 1” female ports, vessel and internals. For small flow rates a cartridge system can be used. These can be bought in 10” and 20” lengths along with standard and “big blue” widths.

Particulate Filters

Particulate filtration is the filtering of solid, undissolved particles from water. The nature and size of solid particles can vary greatly. Some examples are clay particles, sand, organic debris, Iron oxide and Manganese oxide. Particulate filters can be used whether on their own, or more commonly, as

part of a filtration system. Iron and Manganese filter systems for example sometimes use a back-washable particulate filter. The type and size of filter will depend on the water quality and flow rate.

There are two different types of back-washable filters, multimedia and Turbidex. Both types consist of a blue pressure vessel filled with the media and an automatic backwash valve. The purpose of the valve is to periodically backwash the media bed, thus flushing away (to drain) all of the particulate matter that has built up since the previous backwash. The advantage of these systems is that (apart from servicing) they are labour free. There are no bags or cartridges to change, everything is automatic.

Multimedia filters consist of two different grades of sand, gravel and anthracite. This provides a graduated filter bed and can filter down to 25 microns. Anthracite, being carbon based, will also help to remove organics.

Turbidex is a natural ore that has some advantages over sand & gravel filters. The granules have an angular shape, rough surface and micro-porous void spaces as small as 3 microns. This creates a surface area over 100 times greater than sand. The angularity of the granules and the tapered

internal pore spaces allow for reduction of dirt, silt and organic matter suspended in water by bridging, straining and adhesion. The rough surface and internal porosity provide a high surface area, allowing filtration down to 5 microns.

Please refer to the Technical Data Sheet for sizing information on both types of filter.

Cintropur filters consist of a clearbowl housing with an internal bag filter stretched over a central spindle. As water enters the housing, the water is spun around, creating a centrifugal force. Particulates are caught by the bag and can be emptied using a manual purge valve located on the bottom of the housing. The advantages of the Cintropur systems are that they can deal with high flow rates and yet the pressure drops are low. There are a number of different sizes to deal with a wide range of flow rates. The bags can be bought in a range of micron sizes and some are washable.

Please refer to Euraqua catalogue for pricing

These are probably the most popular of all particulate filters. The housings can be bought in standard and wide (big blue) versions as well as 10”, 20”, 30” and 40” lengths. There are also clear bowl options. Cartridges are usually made from wound polypropylene and can be bought in a range of micron sizes. Carbon block cartridges can also be used which have a micron rating.

Please refer to Euraqua catalogue for pricing

Iron, Manganese and Hydrogen Sulphide Removal Filters

When rain falls, the water has a naturally aggressive, slightly acidic nature. This water then dissolves chalk and/or metallic deposits present in the local rock strata, resulting in ground and borehole water containing elements that would not normally be present in mains water. Contaminants such as Iron and Manganese can cause problems such as poor tasting (and potentially harmful) drinking water & staining of appliances and equipment.

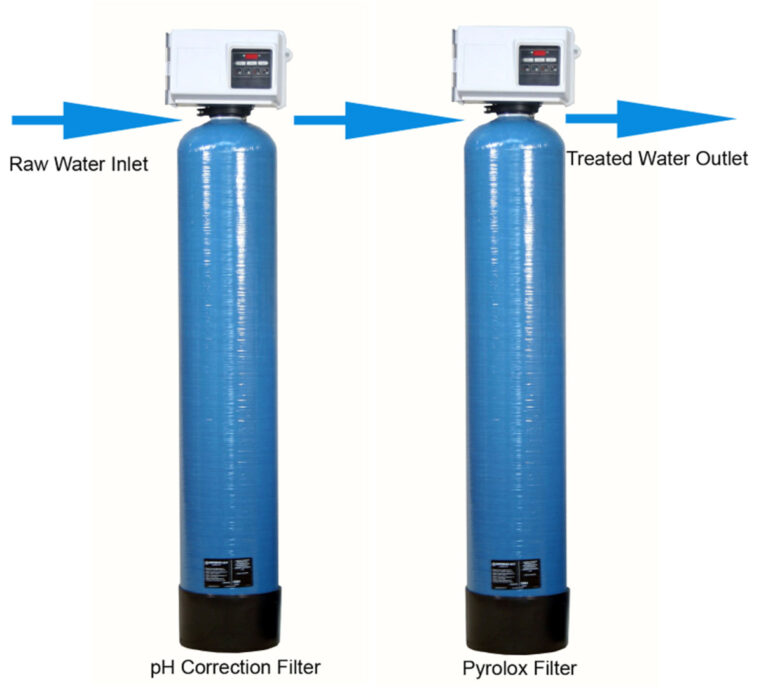

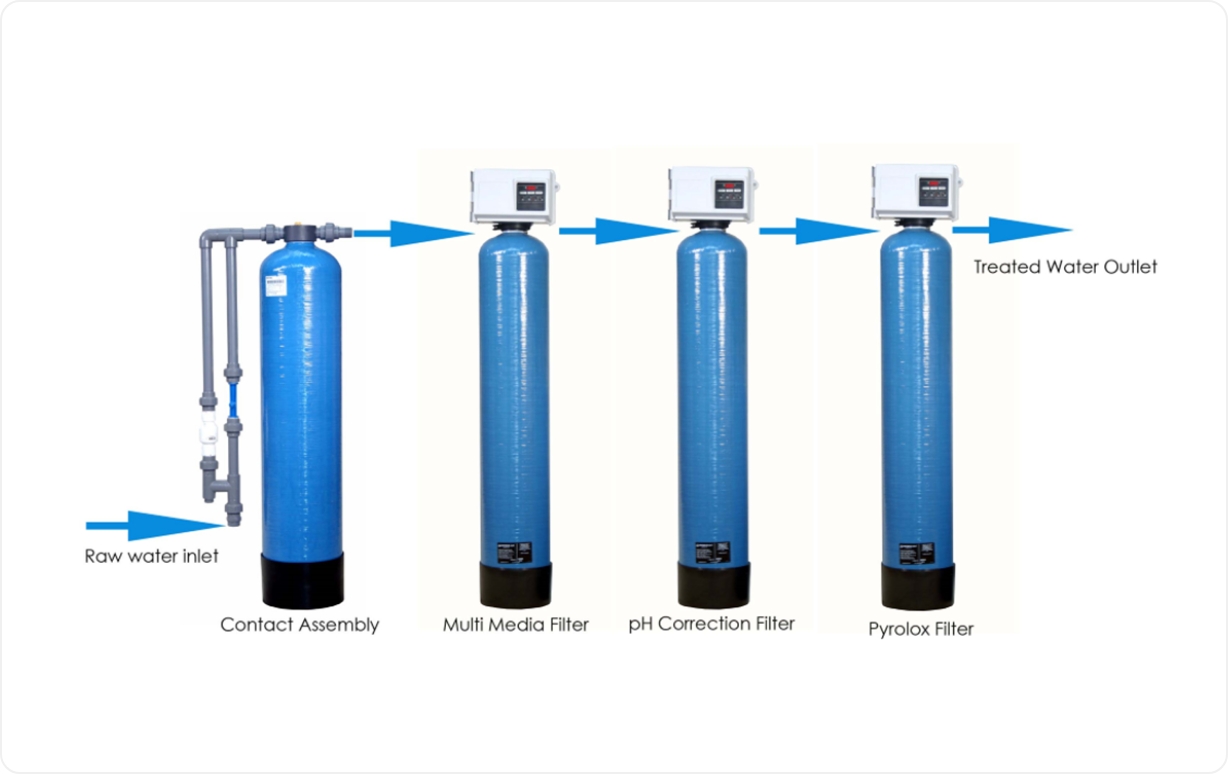

A water analysis should always be the starting point for the specification of an Iron and Manganese removal system. A filtration system can then be tailor made to suit the individual water chemistry. This often involves the use of one or more of the filters shown on the diagram below. These can help the main catalytic filter achieve the desired results.

Contact assemblies are designed to aerate water. Air is drawn in using a Mazzei injector which then mixes inside the vessel, This helps by initiating the oxidation of Iron and Manganese. Precipitation starts to occur which can then be removed using a multi media filter, before the water reaches the main catalytic filter.

Physical filters can be used to remove precipitated Iron and Manganese once passed through a contact assembly. A multi media filter consists of a graduated bed of gravel, sand and anthracite. Filtering down to 25 microns, the backwash valve ensures that the sediment is washed away, thus increasing the life of the catalytic media.

Catalytic media work at their optimum efficiency at higher pH levels. A pH system can therefore be used when the water is acidic and/or the water chemistry is considered unfavourable for Iron and Manganese removal. pH correction media is the only media which is “used up” during the process.

For technical information on sizing with Pyrolux media please refer to Technical Data Sheet.

Nitrate Removal Filters

The presence of Nitrates in water causes many problems, ranging from blue baby syndrome (if fed to babies under 6 months old) to contamination of poultry if used as feed water for farmed birds. The source of Nitrates in groundwater is usually from farming fertilisers. The UK permitted maximum is 50mg/l with an advisory maximum of 25 mg/l.

Nitrate dissolved in water is not able to be removed by simple filtration. It can only be reduced by either regenerable or disposable cartridge type ion exchange systems or eliminated by reverse osmosis. RO systems can be used to treat all of the water for a specific application, or just to remove the Nitrates from a drinking water supply in the kitchen.

For single dwellings with one drinking water tap and low water consumption, a point of use system provides efficient reduction at low cost. For large or multiple properties , commercial and industrial applications, regenerable ion exchange systems will be preferred. It is these systems that are illustrated here.

Ion exchange Nitrate removal is a similar process to water softening, using slightly different polymer resin. The resin removes the Nitrate (and some of the Sulphate due to its chemical similarity) from the water and replaces it with Chloride ions. Once the resin bed is nearly exhausted of Chloride ions,

the control valve carries out a regeneration of the bed.

This is achieved by passing a Chloride rich brine solution (made up from common salt dissolved in water) through the resin bed, which flushes out the Nitrates and Sulphates to drain, replacing them with Chlorides again. After a final rinse to remove excess brine, the unit is automatically put back into service again. The only input required by the user is to ensure that the brine tank is kept topped up with salt.

For fixed or constant flow rates a simple timer controlled valve will suffice. This will affect the regeneration of the resin bed at a pre-set time interval. For varying demands, a water metre controlled unit is more suitable, regenerating only after a set volume of water has passed through the resin bed. With applications that require continuous high flows, a duty / standby “duplex” system will be required. Regeneration is controlled by a valve mounted on top of the pressure vessel containing resin. A solution of brine is drawn through the column and the chloride from the salt displaces the Nitrate and Sulphate ions, flushing them down the drain.

The capacity of a Nitrate removal unit is a function of the amount of resin in the column, the amount of Nitrate and Sulphate, and the amount of salt used at each regeneration. The output will therefore increase or decrease according to local circumstances and the salt dosing rate. The raw water can also change dramatically in composition depending on the season and weather conditions. Commercial and industrial systems are built with separate brine tanks and can be simplex or duplex. They will be assembled with the most suitable valve for the peak flow rate.

Organic Scavenger Filters

Yellow discolouration of water can be caused by organic compounds called tannins. These are usually found in peaty areas and in water supplies that are affected by surface water. Apart from discoloration, organic compounds can make water non potable and can foul filtration and reverse osmosis systems.

Although Carbon filters can be used to remove organics, the media quickly becomes fouled when the organic load is high. Tannex filters consist of a mix of two organic scavenger resins. These have a special porous structure which will capture organic species by a number of different mechanisms. The resins are regenerated using Sodium Chloride brine, using the Chloride ion. The filter therefore operates in a similar way to a softener, with a periodic backwash and regeneration. Brining levels are higher than the equivalent softener — see Technical Data Sheet

A periodic resin wash with caustic soda, typically once every 3 months, is recommended to help prevent irreversible fouling of the media with organic compounds. The caustic soda can be added into the brine well of the brine tank and left to dissolve before manually regenerating the system.

The caustic will be pulled through the vessel, cleaning the media bed.