Custom made solutions

High quality skidded systems, custom engineered and backed up by decades of experience.

For over 20 years we have been offering our customers a unique service within the Pollet Group. As well as stocking a wide range of water treatment products, we are able to build and test complete water treatment systems to suit your requirements. By integrating the products we stock into a customised skidded system, we are able to deliver high quality systems at competitive prices and short lead times.

In most cases we build to our customers’ design specifications but when requested we can provide engineering and process design input, gathered from the many hundreds of diverse systems we have manufactured.

Benefits and features of Euraqua custom built skids:

Examples of some of the systems and markets we have serve include:

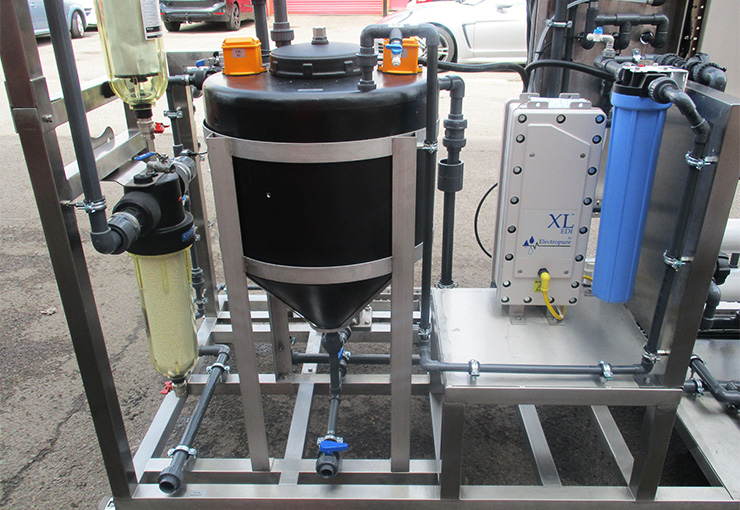

RO and EDI unit with heat sanitisable ring main

Custom engineered RO EDI model to produce 500lph @ <0.1μS

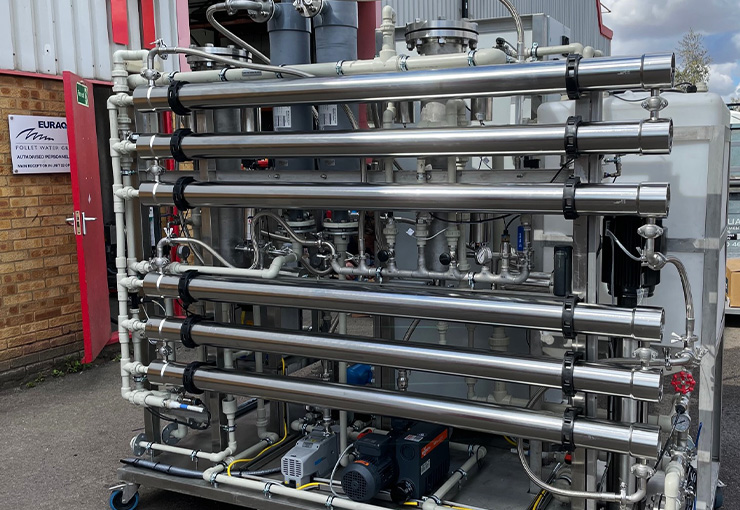

Modularised RO/EDI plant for Waste to Energy boiler feedwater production

RO /EDI unit with sanitisation for Central Sterile Service Department (CSSD) of Hospital

Custom engineered RO/EDI/MB system for ultra pure water production

Duplex Softener, GAC, RO, EDI, Non regenerable Mixed Beds